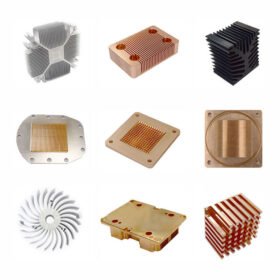

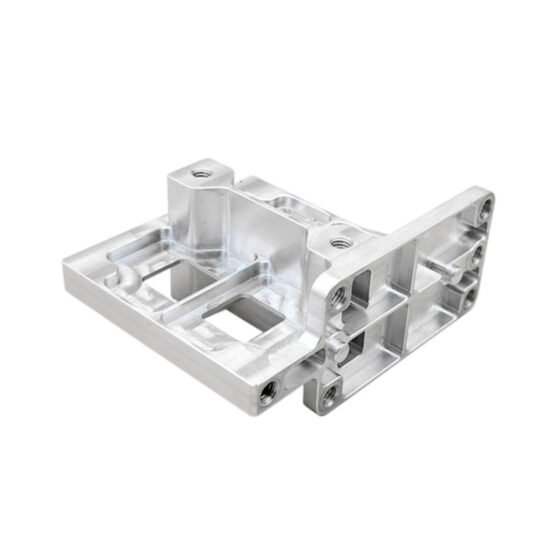

We specialize in CNC turning services for bronze, copper, and brass parts. These materials offer unique properties such as excellent corrosion resistance, high conductivity, and attractive finishes. Our advanced CNC technology ensures precise machining of components for industrial, electrical, ยานยนต์, and decorative applications.

CNC Turning Capabilities:

- Materials We Work With:

- Brass:

- C360 (Free Machining Brass): High machinability, ideal for intricate parts.

- C230 (Red Brass): Corrosion resistance and durability.

- Copper:

- C110 (Electrolytic Tough Pitch Copper): High electrical conductivity.

- C101 (Oxygen-Free Copper): Excellent for electrical and thermal components.

- Bronze:

- C954 (Aluminum Bronze): Superior strength and wear resistance.

- C932 (Bearing Bronze): Ideal for friction-resistant applications.

- Brass:

- Processes:

- Precision turning for cylindrical and symmetrical components.

- Threading, knurling, grooving, and chamfering options.

- Tolerances as tight as ±0.01 mm.

- Part Dimensions:

- Diameter: 1 mm to 300 mm.

- Length: Up to 1,000 mm, customizable based on design.

การใช้งาน:

- Electrical Components:

- Terminals, connectors, and bushings made from copper and brass for high conductivity.

- Plumbing and HVAC Systems:

- Brass and bronze fittings, valves, and adapters for water and gas applications.

- Automotive:

- Bushings, bearings, and decorative trims for durability and aesthetics.

- Industrial Equipment:

- Bronze gears, shafts, and couplings for wear-resistant performance.

- Decorative Hardware:

- Custom knobs, handles, and trims from brass or bronze for premium finishes.

Surface Treatments Available:

- Polishing for a reflective or matte finish.

- Electroplating (nickel, chrome, gold) for durability and aesthetics.

- Anti-corrosion coatings and passivation.

- Sandblasting for textured finishes.

ทำไมต้องเลือกเรา?

- Material Expertise: Extensive experience machining bronze, copper, and brass.

- Custom Solutions: Fully tailored designs to meet your specifications.

- High Precision: Advanced CNC technology for intricate features and tight tolerances.

- Fast Turnaround: Efficient processes to meet your project timelines.

- Scalability: Prototypes to large-scale production runs.