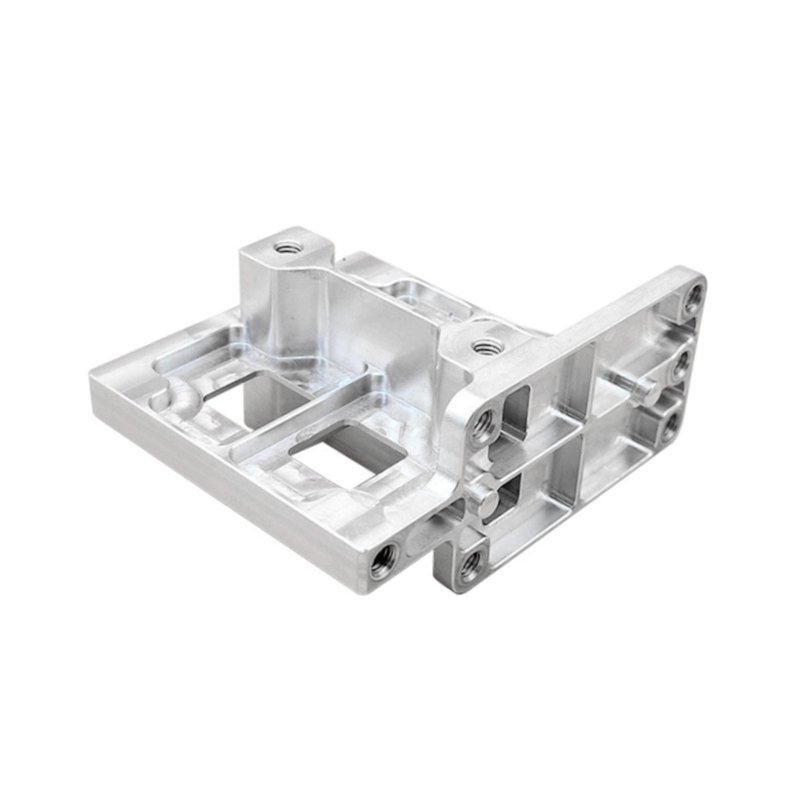

We specialize in manufacturing high-precision aluminum CNC machined parts using advanced turning and milling techniques. Aluminum’s lightweight, excellent machinability, corrosion resistance, and strength make it ideal for diverse applications across automotive, aerospace, medical, electronics, and industrial sectors.

CNC Machining Capabilities for Aluminum:

- CNC Turning:

- Processes: High-speed turning for cylindrical and symmetrical parts.

- Capabilities:

- Threading, grooving, knurling, and chamfering.

- Precision tolerance: ±0.01 mm.

- การใช้งาน:

- Shafts, bushings, housings, and fasteners.

- CNC Milling:

- Processes: 3-axis, 4-axis, and 5-axis milling for complex geometries.

- Capabilities:

- Pockets, slots, and intricate contours.

- Precision tolerance: ±0.005 mm.

- การใช้งาน:

- Enclosures, brackets, heat sinks, and mechanical components.

- Material Grades:

- 6061 Aluminum: General-purpose with excellent strength and corrosion resistance.

- 7075 Aluminum: High-strength aerospace-grade material.

- 5052 Aluminum: Superior corrosion resistance for marine applications.

- 2024 Aluminum: High fatigue resistance for aerospace and military use.

Surface Treatments for Aluminum Parts:

- Anodizing: Clear, colored, or hard anodizing for enhanced durability and aesthetics.

- Polishing: For a reflective or satin finish.

- Powder Coating: For corrosion resistance and custom colors.

- Sandblasting: Matte textures and improved surface uniformity.

- Passivation: Enhanced protection against oxidation.

Applications of Aluminum CNC Machined Parts:

- Automotive:

- Engine components, brackets, housings, and lightweight structural parts.

- Aerospace:

- Aircraft brackets, heat exchangers, and lightweight assemblies.

- Medical:

- Surgical instruments, device housings, and diagnostic equipment parts.

- Electronics:

- Heat sinks, enclosures, and connectors for thermal and electrical management.

- Industrial Equipment:

- Robotic arms, เกียร์, and custom machine parts.

ทำไมต้องเลือกเรา?

- High Precision: Advanced CNC machines ensure tight tolerances and intricate designs.

- Customization: Tailored parts based on customer specifications and CAD designs.

- Scalability: From prototypes to full-scale production runs.

- Quality Assurance: Rigorous inspection and testing for consistent performance.

- Fast Turnaround: Efficient manufacturing to meet project deadlines.