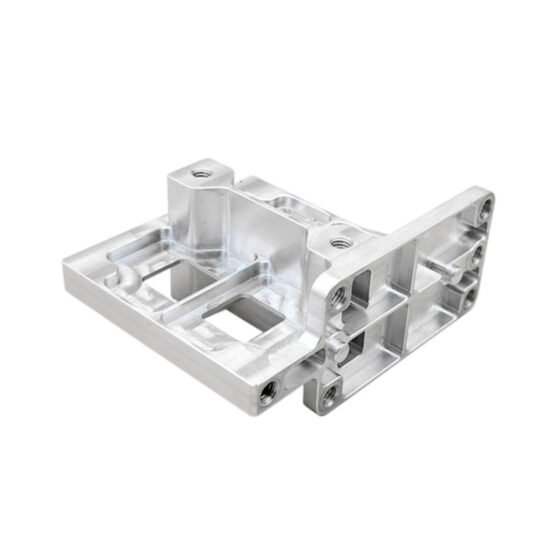

We specialize in precision CNC fabrication of stainless steel heavy-duty jaw triangle fastener clamps. Designed for strength, durability, and corrosion resistance, these clamps are ideal for industrial, mechanical, and structural applications. Using advanced CNC machining techniques, we ensure the highest quality and tight tolerances to meet your specific needs.

Key Features:

- Material Options:

- 304 Stainless Steel: Excellent corrosion resistance for most applications.

- 316 Stainless Steel: Superior resistance to corrosion, ideal for marine and chemical environments.

- 410 Stainless Steel: High strength with moderate corrosion resistance.

- Design and Fabrication:

- CNC Turning: Precision for cylindrical and threaded components.

- CNC Milling: Complex geometries, grooves, and slots for clamp mechanisms.

- Custom Shapes: Tailored jaw and triangle designs for specialized applications.

- Tolerances:

- Precision machining with tolerances as tight as ±0.01 mm.

- Surface Finishing Options:

- Polishing for a smooth, reflective finish.

- Sandblasting for a uniform matte surface.

- Passivation to enhance corrosion resistance.

Applications:

- Industrial Equipment:

- Heavy-duty clamps for assembly lines, conveyor systems, and machinery.

- Construction:

- Fasteners for secure connections in structural assemblies.

- Automotive and Aerospace:

- Components requiring high strength and durability under stress.

- Marine and Chemical Industries:

- Corrosion-resistant clamps for harsh environments.

- OEM and Custom Applications:

- Tailored clamps for specific machinery and devices.