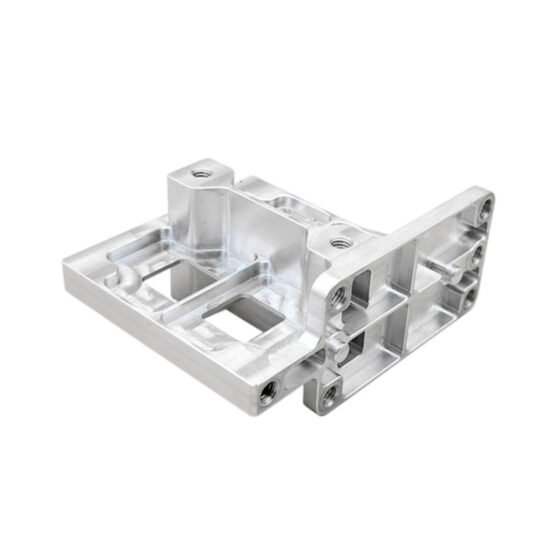

Our stainless steel and titanium CNC machined mechanical parts are manufactured using advanced CNC machining and turning technologies, ensuring high precision, durability, and quality. These components are ideal for applications requiring strength, corrosion resistance, and lightweight properties, commonly used in industries such as aerospace, medical, automotive, and industrial equipment manufacturing.

Material Specifications:

- Stainless Steel Options:

- 304/304L: General-purpose corrosion resistance and strength.

- 316/316L: Superior corrosion resistance, suitable for marine and chemical environments.

- 17-4PH: High strength and excellent corrosion resistance, ideal for aerospace and defense.

- 410/420: Hardenable stainless steel for wear resistance.

- Titanium Options:

- Grade 1: Soft and highly corrosion-resistant, ideal for chemical processing.

- Grade 2: Excellent corrosion resistance with moderate strength.

- Grade 5 (Ti-6Al-4V): High strength-to-weight ratio, widely used in aerospace and medical applications.

- Grade 9: Lightweight and strong, often used for sports and automotive components.

Machining Capabilities:

- CNC Turning: Handles cylindrical components with tight tolerances.

- CNC Milling: 3-axis to 5-axis machining for complex geometries.

- Drilling and Tapping: Precision holes with various threading standards.

- Multi-Axis Machining: Produces intricate parts with high precision and repeatability.

Applications:

- Aerospace:

- Lightweight titanium parts for high-stress environments, such as landing gear, engine components, and fasteners.

- Stainless steel parts for structural integrity and corrosion resistance.

- Medical Devices:

- Biocompatible titanium components for implants, surgical tools, and prosthetics.

- Precision stainless steel components for medical instruments.

- Automotive:

- Titanium and stainless steel fittings, fasteners, and suspension components.

- Lightweight yet strong parts for performance vehicles.

- Industrial Equipment:

- Wear-resistant stainless steel components for heavy machinery.

- High-precision titanium parts for manufacturing equipment.

- Marine and Offshore:

- Corrosion-resistant stainless steel parts for seawater applications.

- Titanium components for lightweight, high-durability marine equipment.

Advantages:

- Durability and Strength: High resistance to wear, corrosion, and stress.

- Lightweight Properties (Titanium): Ideal for weight-sensitive applications.

- Customization: Tailored to meet exact design and application requirements.

- Precision Manufacturing: Tight tolerances and superior finishes for complex designs.

- Versatility: Wide range of material options and machining capabilities.