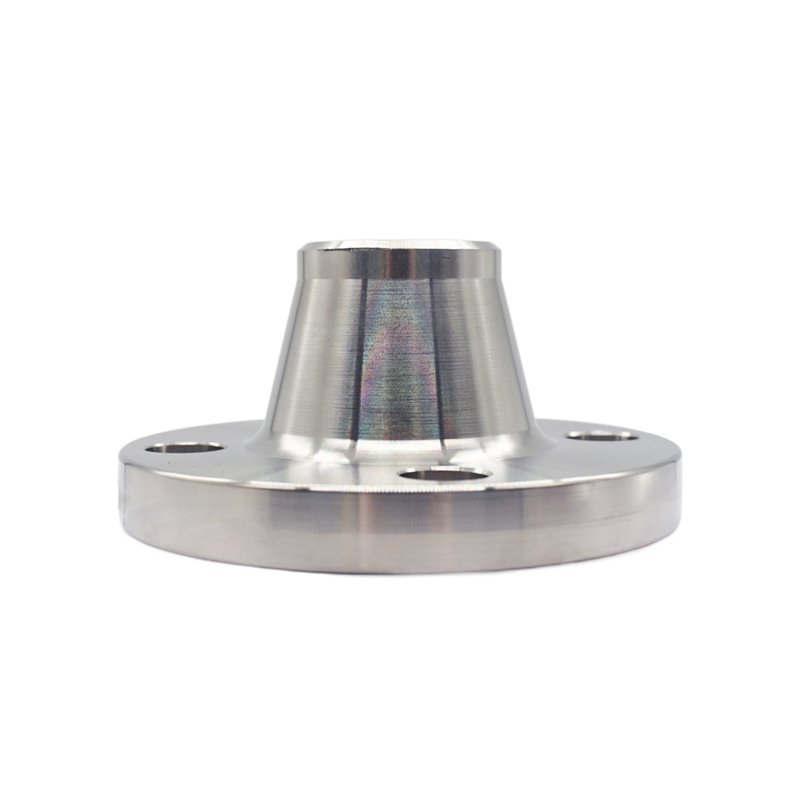

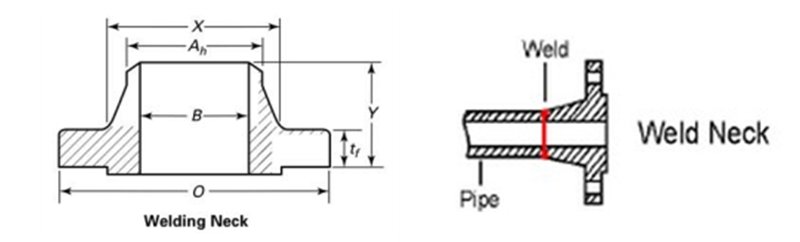

The ASME/ANSI B16.5 Welding Neck (WN) flange is a high-strength flange designed for use in high-pressure and high-temperature applications. Featuring a long tapered hub, the WN flange is welded directly to the pipe, offering exceptional stress distribution and minimizing mechanical stress at the pipe connection. It is ideal for critical applications in industries such as oil and gas, processamento químico, power generation, e mais.

Especificações do Material:

Welding Neck flanges are available in a variety of materials to meet specific operational requirements:

Aço Carbono: ASTM A105, A350 LF2

Aço Inoxidável: ASTM A182 F304, F316, F321

Aço Liga: ASTM A182 F11, F22

Ligas de Níquel: Inconel, Monel, Hastelloy

Aço Inoxidável Duplex: ASTM A182 F51, F53

The choice of material ensures the flange’s suitability for extreme pressures, temperatures, e ambientes corrosivos.

Características Principais:

Tapered Hub Design: Provides smooth transition and stress distribution from the flange to the pipe.

Robust Welding Connection: Ensures a secure and leak-proof joint for critical applications.

Wide Pressure Range: Available in pressure classes from 150 a 2500.

Resistência à corrosão: Excellent material options for corrosive and high-temperature environments.

Dimensional Accuracy: Manufactured in compliance with ASME/ANSI B16.5 standards for precise fit and interchangeability.

Aplicações:

Petróleo & Gas Industry: High-pressure pipelines, refineries, and offshore platforms.

Processamento químico: Piping systems handling aggressive chemicals.

Geração de energia: Steam and cooling systems in thermal and nuclear power plants.

Marine and Offshore: Applications requiring high strength and durability.

Tratamento de água: High-pressure water distribution and desalination systems.

Fixador Asiático

Fixador Asiático