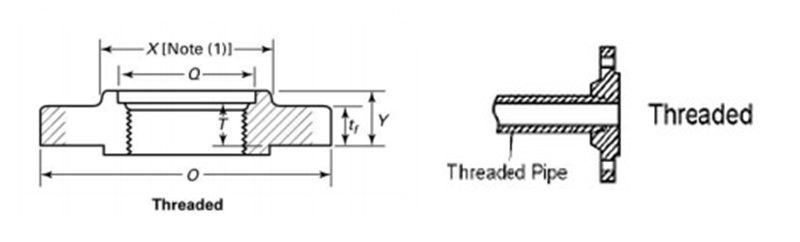

The ASME/ANSI B16.5 Threaded (TH) flange is a specialized flange designed for use in low-pressure, non-welded piping systems. Featuring internal threads, this flange is screwed directly onto the pipe, eliminating the need for welding. It is commonly used in industries where welding is not feasible, such as in explosive environments or temporary connections.

Especificações do Material:

Threaded flanges are manufactured in various materials to suit specific operational requirements:

- Aço Carbono: ASTM A105, A350 LF2

- Aço Inoxidável: ASTM A182 F304, F316, F321

- Aço Liga: ASTM A182 F11, F22

- Ligas de Níquel: Inconel, Monel, Hastelloy

- Aço Inoxidável Duplex: ASTM A182 F51, F53

Material selection is based on the application’s requirements for temperature, pressure, and corrosion resistance.

Características Principais:

- No Welding Required: Ideal for applications where welding is impractical or hazardous.

- Internal Thread Design: Screws directly onto the pipe for a secure connection.

- Cost-Efficient: Reduces installation time and labor costs.

- Pressure Range: Typically used for lower-pressure applications (Class 150, 300).

- Compliance with Standards: Manufactured to ASME/ANSI B16.5 specifications for accuracy and interchangeability.

Aplicações:

- Petróleo & Gás: Non-welded pipeline connections in explosive environments.

- Processamento químico: Systems handling non-corrosive or mildly corrosive fluids.

- Plumbing: Low-pressure water and gas distribution systems.

- Proteção Contra Incêndios: Temporary or modular sprinkler systems.

- Maintenance and Repairs: Temporary or removable pipe connections.

Fixador Asiático

Fixador Asiático