The ASME/ANSI B16.5 Slip-On (SO) flange is a versatile and cost-effective flange designed to slide over the pipe and be welded in place. It is suitable for lower-pressure applications and is widely used in various industries such as oil and gas, water treatment, processamento químico, and general piping systems. Its simple design and ease of installation make it a popular choice for non-critical applications.

Especificações do Material:

Slip-On flanges are available in a range of materials to meet different operational requirements:

- Aço Carbono: ASTM A105, A350 LF2

- Aço Inoxidável: ASTM A182 F304, F316, F321

- Aço Liga: ASTM A182 F11, F22

- Ligas de Níquel: Inconel, Monel, Hastelloy

- Aço Inoxidável Duplex: ASTM A182 F51, F53

The material selection ensures the flange’s performance in various environments, including corrosive and high-temperature conditions.

Características Principais:

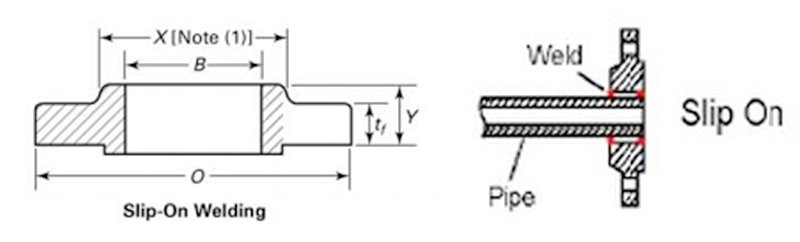

- Simple Design: Slides over the pipe for easy positioning and welding.

- Ease of Installation: Requires only two fillet welds for attachment.

- Cost-Effective: Lower production cost compared to other flange types like Welding Neck flanges.

- Versatility: Suitable for a wide range of piping systems and applications.

- Standard Compliance: Manufactured in accordance with ASME/ANSI B16.5 for precise dimensions and interchangeability.

Aplicações:

- Petróleo & Gás: Low-pressure pipelines and non-critical connections.

- Tratamento de água: Desalination and water distribution systems.

- Processamento químico: Piping systems handling non-corrosive or mildly corrosive fluids.

- Sistemas HVAC: Heating, ventilação, and cooling applications.

- General Industrial Piping: Various fluid and gas transfer systems.

Fixador Asiático

Fixador Asiático