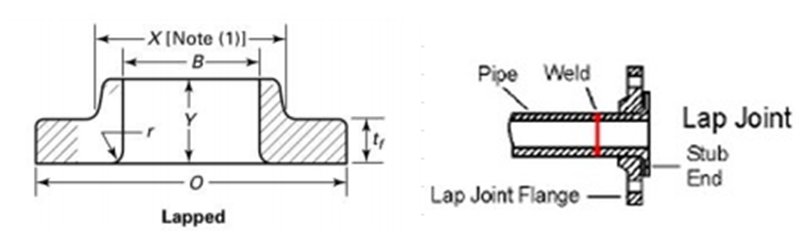

The ASME/ANSI B16.5 Lap Joint (LJ) flange is a two-piece component consisting of a backing flange and a stub end. This design allows the flange to rotate freely around the pipe, facilitating easy alignment during installation. It is commonly used in systems requiring frequent dismantling for inspection or cleaning, such as those in the chemical, food processing, and water treatment industries.

Especificações do Material:

Lap Joint flanges are available in a range of materials to meet application-specific requirements:

- Backing Flange Materials: Typically carbon steel or stainless steel for cost efficiency.

- Stub End Materials:

- Aço Carbono: ASTM A105, A350 LF2

- Aço Inoxidável: ASTM A182 F304, F316, F321

- Ligas de Níquel: Inconel, Monel, Hastelloy

- Aço Inoxidável Duplex: ASTM A182 F51, F53

Material selection ensures compatibility with the pipe material and process conditions, including corrosion and temperature resistance.

Características Principais:

- Rotatable Design: Facilitates easy alignment with bolt holes during assembly.

- Economical Option: Backing flange can be made from less expensive materials, reducing costs.

- Ease of Maintenance: Ideal for systems requiring frequent dismantling or inspection.

- Stress Reduction: The loose connection minimizes stress transfer from the flange to the pipe.

- Standard Compliance: Manufactured per ASME/ANSI B16.5 standards for precise dimensions and interchangeability.

Aplicações:

- Processamento químico: Ideal for corrosive fluid systems requiring regular maintenance.

- Indústria Alimentar e de Bebidas: Hygienic systems needing easy disassembly for cleaning.

- Tratamento de água: Pipelines in desalination, wastewater, and distribution systems.

- Pharmaceuticals: Systems with strict sanitary requirements.

- Petróleo & Gás: Non-critical applications or low-pressure piping systems.

Fixador Asiático

Fixador Asiático