We offer precision CNC machining services for brass parts, including both milled and turned components. Brass is a highly machinable material known for its excellent corrosion resistance, thermal and electrical conductivity, and attractive finish, making it ideal for a wide range of industrial and decorative applications.

Key Features of Brass CNC Machined Parts:

- Precision:

- Tolerances up to ±0.005 mm for milled parts and ±0.01 mm for turned parts.

- Material Grades:

- C360 Brass: Free-machining brass, perfect for high-speed machining.

- C268 Brass: Yellow brass, strong and ductile.

- C280 Brass: Muntz metal, used for structural applications.

- C230 Brass: Red brass with superior corrosion resistance.

- Machining Capabilities:

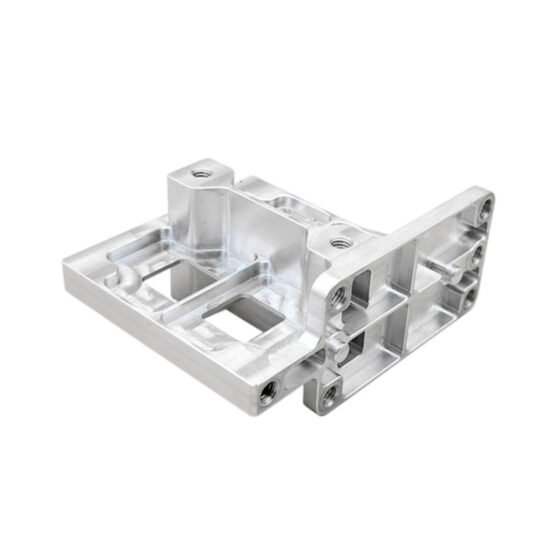

- CNC Milling: Complex geometries, pockets, slots, and detailed contours.

- CNC Turning: Cylindrical parts with threading, knurling, and grooving options.

Surface Treatments for Brass Parts:

- Polishing for a bright and reflective finish.

- Nickel and chrome plating for enhanced corrosion resistance.

- Sandblasting for matte textures.

- Protective coatings for long-term durability.

Applications of Brass CNC Parts:

- Electronics:

- Terminals, connectors, and pins for their excellent conductivity.

- Plumbing:

- Fittings, valves, and adapters due to brass’s water and corrosion resistance.

- Automotive:

- Bushings, bearings, and precision fasteners for their durability.

- Aerospace:

- Lightweight and durable components for critical systems.

- Decorative Hardware:

- Handles, knobs, and decorative trims for furniture and architectural applications.

Fixador Asiático

Fixador Asiático