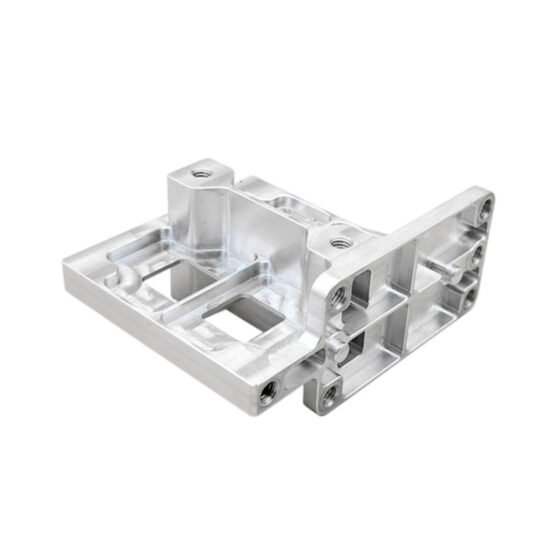

We provide custom CNC machined and milled aluminum parts with anodized finishes, tailored to your specific design and functionality requirements. Our advanced CNC machining capabilities ensure precise fabrication, tight tolerances, and excellent surface quality, ideal for industries such as aerospace, automotive, electronics, and medical equipment.

Key Features:

- Material Options:

- 6061 Aluminum: General-purpose, corrosion-resistant, and strong.

- 7075 Aluminum: Aerospace-grade with exceptional strength-to-weight ratio.

- 5052 Aluminum: Excellent for marine applications due to its corrosion resistance.

- 2024 Aluminum: High fatigue resistance, suitable for aerospace applications.

- Precision CNC Machining:

- Milling: 3-axis, 4-axis, and 5-axis CNC milling for complex geometries and intricate details.

- Tolerances: Tight tolerances up to ±0.005 mm for critical dimensions.

- Customization: Drilling, threading, pocketing, and engraving based on specifications.

- Anodized Surface Finishes:

- Color Anodizing: Wide range of colors for aesthetic and functional purposes.

- Hard Anodizing: Enhanced wear and corrosion resistance for heavy-duty applications.

- Clear Anodizing: Protects the aluminum while maintaining its natural appearance.

Applications:

- Aerospace:

- Lightweight structural components and brackets.

- Automotive:

- Engine parts, housings, and decorative trims.

- Electronics:

- Heat sinks, enclosures, and connectors.

- Medical Devices:

- Surgical tools, diagnostic equipment parts, and housings.

- Industrial Equipment:

- Custom components for machines and assemblies.