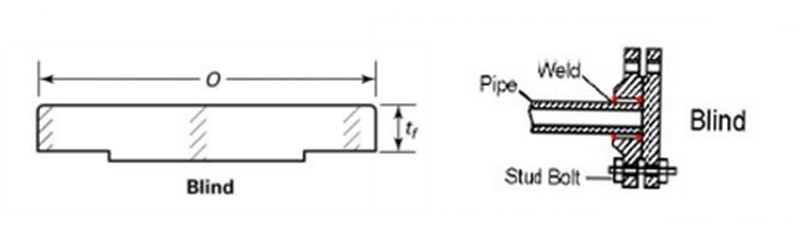

The ASME/ANSI B16.5 Blind (BL) flange is a solid flange with no center bore, designed to close or seal the end of a piping system, valve, or pressure vessel. It is commonly used in systems requiring isolation, inspection, or maintenance. Blind flanges can withstand high pressures and are versatile for use in various industries, including oil and gas, chemical processing, power generation, and water treatment.

Material Specifications:

Blind flanges are available in a variety of materials to meet diverse application requirements:

- Carbon Steel: ASTM A105, A350 LF2

- Stainless Steel: ASTM A182 F304, F316, F321

- Alloy Steel: ASTM A182 F11, F22

- Nickel Alloys: Inconel, Monel, Hastelloy

- Duplex Stainless Steel: ASTM A182 F51, F53

Material selection ensures excellent performance in high-pressure, high-temperature, or corrosive environments.

Key Features:

- Solid Design: Provides a secure and leak-proof seal for pipe ends or vessels.

- High Strength: Capable of handling extreme pressure and temperature conditions.

- Versatile Compatibility: Fits piping systems of various materials and dimensions.

- Customizable Options: Available in multiple sizes, pressure ratings, and surface finishes.

- Compliance: Manufactured according to ASME/ANSI B16.5 standards for dimensional accuracy and reliability.

Applications:

- Oil & Gas: Isolating sections of pipelines during maintenance or testing.

- Chemical Processing: Sealing off systems handling corrosive or hazardous fluids.

- Power Generation: High-pressure systems in thermal and nuclear plants.

- Water Treatment: Capping off pipelines in desalination and wastewater systems.

- Process Engineering: Temporary closures during system upgrades or repairs.