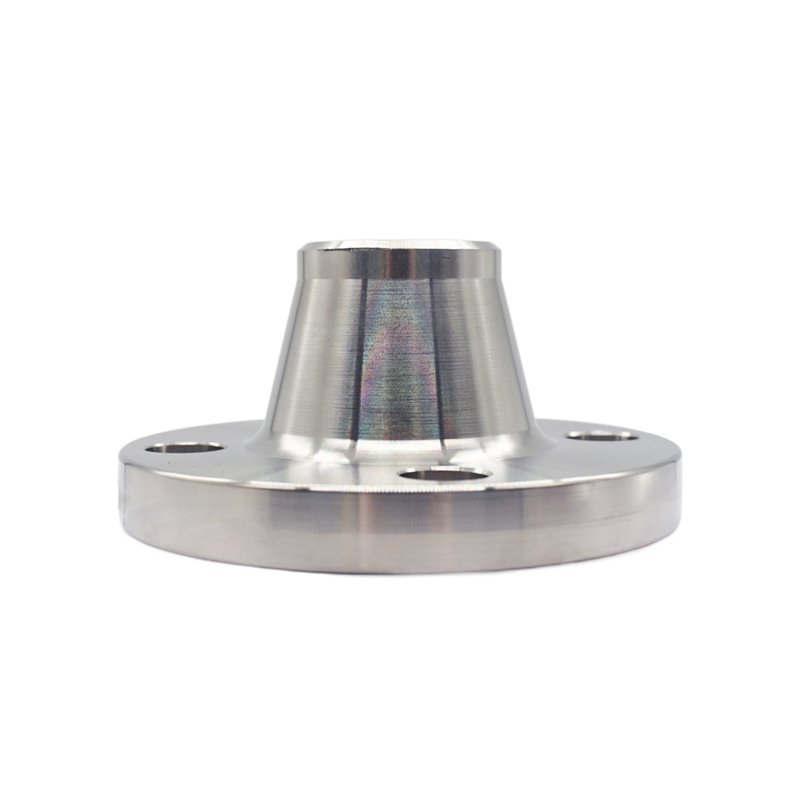

The ASME/ANSI B16.47 Series A and B Welding Neck (WN) flanges are high-strength flanges designed for large-diameter piping systems. These flanges feature a long tapered hub that ensures excellent stress distribution, making them suitable for high-pressure and high-temperature applications. Series A flanges are designed for higher stress tolerance, while Series B flanges are more compact and typically used in applications with less severe conditions.

Material Specifications:

Welding Neck flanges in Series A and B are manufactured in a wide range of materials to meet various operational requirements:

- Carbon Steel: ASTM A105, A350 LF2

- Stainless Steel: ASTM A182 F304, F316, F321

- Alloy Steel: ASTM A182 F11, F22

- Nickel Alloys: Inconel, Monel, Hastelloy

- Duplex Stainless Steel: ASTM A182 F51, F53

Material selection ensures the flange’s performance in extreme conditions such as high pressure, high temperature, or corrosive environments.

Key Features:

- Long Tapered Hub: Provides smooth stress distribution and minimizes mechanical stress at the weld.

- High Strength: Ideal for critical applications requiring robustness and durability.

- Pressure Classes: Available in Class 75 through Class 900, covering a wide range of pressure needs.

- Versatility: Series A for critical applications and Series B for less demanding systems.

- Compliance: Manufactured to ASME/ANSI B16.47 standards for dimensions and reliability.

Applications:

- Oil & Gas: High-pressure pipelines, offshore platforms, and refineries.

- Chemical Processing: Systems handling corrosive or hazardous fluids.

- Power Generation: High-temperature steam and cooling systems.

- Marine and Offshore: Large-diameter piping systems for ships and offshore installations.

- Water Treatment: Piping systems in desalination plants and wastewater management.

Fixation asiatique

Fixation asiatique