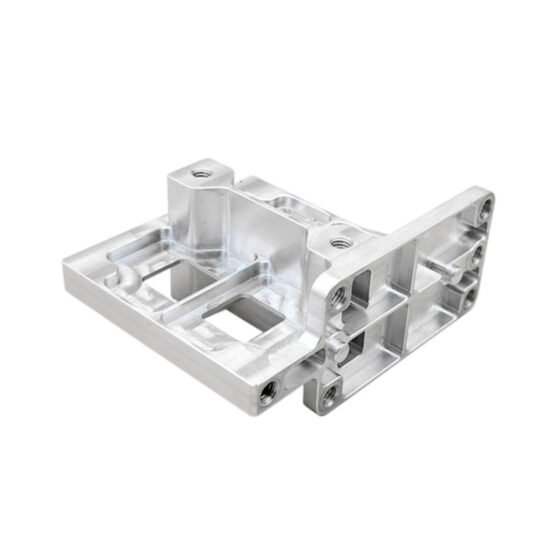

We specialize in manufacturing precision CNC metal turning parts using stainless steel and aluminum. Our advanced CNC machining technology ensures high accuracy, excellent surface finish, and durability, making these parts suitable for a wide range of applications, including automotive, aerospace, medical, and industrial sectors.

Hauptmerkmale:

- Material Options:

- Edelstahl:

- 304: Excellent corrosion resistance and strength.

- 316: Superior corrosion resistance, ideal for marine and chemical environments.

- 410: High strength and wear resistance.

- Aluminum:

- 6061: Lightweight, corrosion-resistant, and strong.

- 7075: Aerospace-grade material with exceptional strength.

- 5052: Excellent corrosion resistance, ideal for marine applications.

- Edelstahl:

- Precision Manufacturing:

- CNC Turning: Cylindrical parts with tight tolerances of ±0.01 mm.

- Customization: Threads, grooves, knurling, and chamfering tailored to specifications.

- Dimensional Range:

- Diameter: 1 mm to 500 mm.

- Length: Up to 2,000 mm, fully customizable.

- Surface Finishes:

- Polishing for a smooth or reflective finish.

- Anodizing (for aluminum) to enhance durability and aesthetics.

- Passivation (for stainless steel) to increase corrosion resistance.

- Sandblasting for a matte or textured surface.

Anträge:

- Automotive:

- Engine components, bushings, and fasteners.

- Aerospace:

- Lightweight structural parts and precision components.

- Medical Equipment:

- Stainless steel surgical tools and device components.

- Industrial Machinery:

- Shafts, Getriebe, and connectors for high-performance machines.

- Electronics:

- Aluminum housings, heat sinks, and brackets.

Asiatischer Verschluss

Asiatischer Verschluss