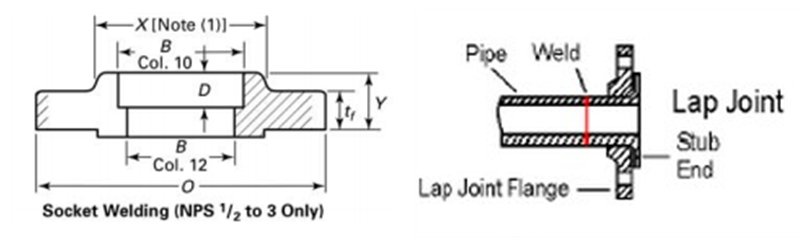

The ASME/ANSI B16.5 Socket Weld (SW) flange is a high-performance flange designed for use in small-diameter, high-pressure piping systems. Featuring a socket for the pipe to fit into, the SW flange is secured through a single fillet weld at the pipe connection. This design ensures a leak-proof joint and offers excellent strength and durability, making it suitable for critical applications in industries such as oil and gas, Chemische Verarbeitung, und Stromerzeugung.

Materialspezifikationen:

Socket Weld flanges are available in a range of materials to meet application requirements:

- Kohlenstoffstahl: ASTM A105, A350 LF2

- Edelstahl: ASTM A182 F304, Nr. F316, Nr. F321

- Stahllegierung: ASTM A182 F11, F22

- Nickel-Legierungen: Inconel, Monel, Hastelloy

- Duplex Edelstahl: ASTM A182 F51, Nr. F53

Material selection is based on operational needs such as pressure, Temperatur, and resistance to corrosion.

Hauptmerkmale:

- Socket Design: Ensures accurate pipe alignment and a secure fit.

- High Strength: Ideal for high-pressure and high-temperature systems.

- Leak-Proof Connection: Fillet weld provides a strong, durable seal.

- Compact Design: Suitable for applications with space constraints.

- Einhaltung von Standards: Manufactured according to ASME/ANSI B16.5 specifications for dimensional accuracy and reliability.

Anträge:

- Öl & Gas: High-pressure pipelines and offshore installations.

- Chemische Verarbeitung: Piping systems handling aggressive chemicals.

- Stromerzeugung: Steam and cooling systems in thermal and nuclear plants.

- Petrochemie: Critical piping in refineries and petrochemical plants.

- Wasseraufbereitung: High-pressure water distribution systems.

Asiatischer Verschluss

Asiatischer Verschluss